Technical data:

• Flexible screened PVC data and control cable

Temperature range:

• -25°C to +105°C

Nominal voltage:

• 300 V

Test voltage:

• 2000 V

Minimum Bending Radius:

• Flexing 6x cable Ø

Coupling Resistance:

• Max. 250 Ohm/km

Radiation Resistance:

• Up to 80x106 cJ/kg (up to 80 Mrad)

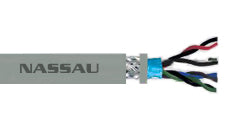

Cable Structure:

• Tinned copper conductor, fine wire stranded, with AWG dimensions

• Core insulation of special PVC (AWG 22 - AWG 18 with transparent nylon skin)

• Core identification (pair) acc. to international colour code

• Cores stranded in pairs with optimal lay length

• Pairs stranded in layers with optimal lay length

• 1. Screening with special aluminium foil

• Drain wire

• 2. Tinned copper braided screen, approx. 85% coverage

• Separator

• Outer sheath of special PVC

• Sheath colour: grey (RAL 7001)

• With length marking in feet

Properties:

• The materials used during manufacturing are cadmium-free, contain no silicone and are free from substances harmful to the wetting properties of lacquers

Tests:

• Self-extinguishing and flame retardant acc. to CSA FT4

UL (AWG 22 - AWG 18):

• PLTC-ER, ITC-ER, CM, NFPA 79, OIL RES I & II, Class I Div. 2, NEC Art. 501, 725, 760 & 800, AWM 2517

UL (AWG 24 - AWG 26):

• CM, AWM 2517, rated OIL RES I & II, NEC Art. 725, 760 & 800, NFPA 79

CSA:

• CSA CMG FT4, AWM I/II A/B FT4

Note:

Advantages:

• Highly flexible, easy to install

• Oil resistant to OIL RES I & II

Available on request:

• PUR or TPE outer sheath

• Sheath colour to suit customer requirement

Application:

• HELUKABEL TRAYCONTROL 300-C TP is a screened, twisted pair data and control cable. Cross-sections with PLTC-ER and ITC-ER approval suitable for open, unprotected installation in cable trays to the machine; their outstanding oil resistance (OIL RES I & II) makes them ideally suited as connecting and joining cables and also for control, signal and measuring systems in industrial plants. The flexible cable structure facilitates installation inside and outside of machines and switch cabinets. The double-screening with aluminium foil (100% coverage) and copper braid (approx. 85% coverage) guarantee superior EMC protection. Applications: tool machines, control panels, measuring devices, production automation, cable ducts, renewable energies. EMC = Electromagnetic compatibility To optimize the EMC features we recommend a large round contact of the copper braiding on both ends. = Product conforms with Low-Voltage Directive 2014/35/EU.

| technical specification: | |

| awg-no. | 22 |

| no.pairs x no.cores | 25 x 2 |

| cross section mm² | 0,382 |

| outer ø app. mm | 23,1 |

| cop. weight kg/km | 239,0 |

| weight app. kg/km | 402,0 |

| helukabel part number | 59812 |