Product Details

Technical Data:

• PVC motor supply cable acc. to UL Std.1277 and UL Std.2277

Temperature Range:

• -25°C to +90°C

Nominal Voltage:

• TC 600 V

• WTTC 1000 V

Test Voltage:

• 4000 V

Minimum Bending Radius:

• flexing 6x cable Ø

Coupling Resistance:

• max. 250 Ohm/km

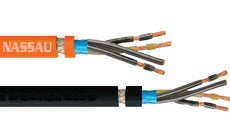

Cable Structure:

• Tinned copper conductor, fine wire with AWG dimensions

• Special PVC core insulation with transparent nylon skin

• Black cores with continuous white numbering

• GN-YE conductor in the outer layer

• Cores stranded in layers with optimal lay length

• Fleece

• 1. Screening with special aluminium foil, 2. Screening with braid of tinned copper wires, optimal coverage approx. 85%

• Separator

• Special PVC outer sheath

• Sheath colour: black (RAL 9005) or orange (RAL 2003)

• With length marking in feet

Properties:

• The materials used during manufacturing are cadmium-free, contain no silicone and are free from substances harmful to the wetting properties of lacquers

• UV resistant

Tests:

• Self-extinguishing and flame retardant acc. to CSA FT4

UL:

• TC-ER, WTTC 1000 V, MTW, NFPA 79, PLTC-ER (AWG 18 - AWG 12), ITC-ER (AWG 18 - AWG 12) OIL RES I & II, 90°C dry / 75°C wet, -40°C Cold Bend Test, Class 1 Div. 2 per NEC Art. 336, 392, 501

CSA:

• c (UL) CIC-TC FT4, AWM I/II A/B FT4

Note:

• VFD = Variable Frequency Drive

Application:

•Flexible, extremely oil resistant motor supply cable for modern servomotors; the double screening with special aluminium foil (100% coverage) and tinned copper braid (approx. 85% coverage) provides effective protection against electrical disturbance and the resultant failures. NFPA 79 approved for open, unprotected installation on cable trays and from cable trays to the machine. The special PVC sheath is extremely resistant to oil, coolants and solvents and hence the perfect solution for industrial applications with open installation, installation in pipes and in the ground.

•EMC = Electromagnetic compatibility

•To optimize the EMC features we recommend a large round contact of the copper braiding on both ends.

•= Product conforms with Low-Voltage Directive 2014/35/EU.

| awg-no. | no.cores x cross-sec.mm² |

weight app. kg / km |

helukabel part number |

Action |

| sheath colour black | ||||

| 18 | 4 X 0,963 | 164,0 | 63139 | Request A Quote |

| 16 | 4 X 1,31 | 183,0 | 63140 | Request A Quote |

| 14 | 4 X 2,08 | 197,0 | 63137 | Request A Quote |

| 12 | 4 X 3,31 | 267,0 | 63141 | Request A Quote |

| 10 | 4 X 5,26 | 402,0 | 63142 | Request A Quote |

| 8 | 4 X 8,37 | 668,0 | 63143 | Request A Quote |

| 6 | 4 X 13,31 | 918,0 | 63144 | Request A Quote |

| 4 | 4 X 21,21 | 1363,0 | 63145 | Request A Quote |

| 2 | 4 X 33,6 | 1994,0 | 63146 | Request A Quote |

| sheath colour orange | ||||

| 18 | 4 X 0,963 | 164,0 | 63147 | Request A Quote |

| 16 | 4 X 1,31 | 183,0 | 63148 | Request A Quote |

| 14 | 4 X 2,08 | 197,0 | 63149 | Request A Quote |

| 12 | 4 X 3,31 | 267,0 | 63150 | Request A Quote |

| 10 | 4 X 5,26 | 267,0 | 63151 | Request A Quote |

| 8 | 4 X 8,37 | 668,0 | 63152 | Request A Quote |

| 6 | 4 X 13,31 | 818,0 | 63153 | Request A Quote |

| 4 | 4 X 21,21 | 1363,0 | 63154 | Request A Quote |

| 2 | 4 X 33,6 | 1994,0 | 63155 | Request A Quote |