Product Details

Overview:

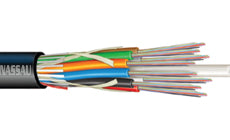

• Prysmian’s ExtremeLink® cables provide robust performance for aerial lashed, duct, and direct buried installations under extreme cold, with rated operation to -50?C even for double armored cables. These heavy duty loose tube cables also support cold temperature operation with extended buffer tube storage up to 20 feet (6 meters) as required for certain outside plant pedestal and enclosures.

• This heavy duty version combines ezPREP® armor, flexible buffer tubes and swellable water-blocking materials make ExtremeLink® the easiest to use heavy duty loose tube cable available today.

Product Snapshot:

Applications: Multi-purpose outdoor - aerial lashed, duct, direct buried

Constructions: Dielectric, armored, double armored

Fiber Count: 2 to 288 fibers in color-coded buffer tubes

Fiber Types: Single-mode / bend-insensitive / NZDSF / Multimode / Hybrid

Options: Gel-free buffer tubes / steel central member / copper pair(s) / tonewire

Other Versions: ExpressLT / LT 2.0 & flame rated

Performance: ANSI / ICEA 640, RUS 7 CFR 1755 (RUS LISTED), Telcordia GR20 and IEC 60794-3-11

Registered Supplier: ISO 9001, ISO 14001, TL 9000, and OHSAS 18001

Feature and Benefits:

Easy Cable Entry and Preparation:

• ezPREP® armor greatly improves mid-span entry

• Ripcord speeds cable entry & outer jacket removal

• Dry core design with swellable binders speed cable preparation

Flexible Routing and Termination:

• Cold temp operation with extended buffer tube storage up to 20 ft.

• Flexible buffer tubes simplify routing & splicing preparation

• Available with bend-insensitive single-mode fiber

Multi-Purpose Installation and Use:

• Suitable for aerial lashed, duct, and direct buried installation

• Small diameter and light weight extend reel and installation lengths

• Optional EzPREP® corrugated steel tape armor provides mechanical protection and rodent resistance

Reliable Lifetime Performance:

• Guaranteed standards-based performance to -50?C

• Proven water-blocking with swellable core elements and gel-filled buffer tubes

| fiber count | # of buffer tubes |

diameter inches (mm) |

approximate cable weight lb/kft (kg/km) |

bend radius | load inches (cm) |

bend radius | no load inches (cm) |

| dielectric (non-armored) (e3h1jkt) | |||||

| 2 - 60 | 5 | 0.46 (11.6) | 65 (97) | 9 (24) | 5 (12) |

| 62 - 72 | 6 | 0.50 (12.6) | 78 (116) | 10 (26) | 5 (12) |

| 74 - 96 | 8 | 0.58 (14.7) | 98 (146) | 12 (30) | 6 (15) |

| 98 - 120 | 10 | 0.65 (16.5) | 120 (179) | 13 (34) | 7 (17) |

| 122 - 216 | 12 to 18 | 0.73 (18.5) | 153 (227) | 15 (37) | 7 (17) |

| 218 - 264 | 22 | 0.81 (20.7) | 183 (273) | 16 (41) | 8 (21) |

| 266 - 288 | 24 | 0.85 (21.5) | 198 (294) | 17 (43) | 9 (22) |

| Single Jacket, Armored (SP) (E3H1A1J) | |||||

| 2 - 60 | 5 | 0.52 (13.2) | 111 (165) | 10 (26) | 8 (20) |

| 62 - 72 | 6 | 0.55 (14.0) | 127 (189) | 11 (28) | 8 (21) |

| 74 - 96 | 8 | 0.64 (16.3) | 157 (234) | 13 (33) | 10 (25) |

| 98 - 120 | 10 | 0.72 (18.3) | 184 (274) | 14 (37) | 11 (28) |

| 122 - 216 | 12 to 18 | 0.81 (20.6) | 225 (335) | 16 (41) | 12 (31) |

| 218 - 264 | 22 | 0.88 (22.4) | 263 (392) | 18 (45) | 13 (34) |

| 266 - 288 | 24 | 0.92 (23.4) | 282 (419) | 18 (47) | 14 (35) |

| Double Jacket, Armored (PSP) (E3H1A2J) | |||||

| 2 - 60 | 5 | 0.60 (15.1) | 148 (220) | 12 (31) | 9 (23) |

| 62 - 72 | 6 | 0.64 (16.3) | 167 (248) | 13 (33) | 10 (25) |

| 74 - 96 | 8 | 0.71 (18.0) | 198 (295) | 14 (37) | 11 (28) |

| 98 - 120 | 10 | 0.78 (19.8) | 235 (349) | 16 (41) | 12 (31) |

| 122 - 216 | 12 to 18 | 0.85 (21.6) | 279 (415) | 17 (44) | 13 (33) |

| 218 - 264 | 22 | 0.95 (24.1) | 321 (478) | 19 (48) | 14 (36) |

| 266 - 288 | 24 | 0.98 (24.9) | 338 (503) | 20 (50) | 15 (38) |

| Double Jacket, Double Armored (SPSP) (E3H2A2J) | |||||

| 2 - 60 | 5 | 0.73 (18.5) | 241 (359) | 15 (37) | 11 (28) |

| 62 - 72 | 6 | 0.77 (19.6) | 265 (395) | 15 (39) | 12 (29) |

| 74 - 96 | 8 | 0.86 (21.8) | 313 (465) | 17 (44) | 13 (33) |

| 98 - 120 | 10 | 0.93 (23.6) | 355 (528) | 19 (47) | 14 (35) |

| 122 - 216 | 12 to 18 | 1.01 (25.7) | 411 (612) | 20 (51) | 15 (39) |

| 218 - 264 | 22 | 1.09 (27.7) | 466 (693) | 22 (55) | 16 (42) |

| 266 - 288 | 24 | 1.13 (28.7) | 492 (732) | 23 (57) | 17 (43) |

| Triple Jacket, Double Armored (PSPSP) (E3H2A3J) | |||||

| 2 - 60 | 5 | 0.80 (20.2) | 294 (438) | 16 (41) | 12 (31) |

| 62 - 72 | 6 | 0.84 (21.3) | 321 (478) | 17 (43) | 13 (32) |

| 74 - 96 | 8 | 0.93 (23.6) | 369 (548) | 19 (47) | 14 (35) |

| 98 - 120 | 10 | 1.01 (25.7) | 421 (626) | 20 (51) | 15 (39) |

| 122 - 216 | 12 to 18 | 1.08 (27.4) | 478 (712) | 22 (55) | 16 (41) |

| 218 - 264 | 22 | 1.16 (29.5) | 537 (799) | 23 (59) | 17 (44) |

| 266 - 288 | 24 | 1.19 (30.2) | 560 (834) | 24 (60) | 18 (45) |

Tensile Rating

| maximum installation load: | 600 lbf | (2700 n) |

| maximum operation load: | 180 lbf | (800 n) |

Temperature Range

| shipping and storage: | -58° f to +167° f | (-50° c to +75° c) |

| installation: | -22° f to +140° f | (-30° c to +60° c) |

| operation: | -58° f to +158° f | (-50° c to +70° c) |