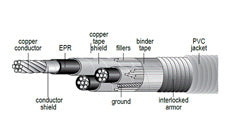

The Interlocked Armor Power Cable – 350MCM - 3 Conductor - 5KV/8KV employs three conductors made from soft bare annealed copper available in compressed or compact stranding. The copper conductors meet ASTM requirements B-3 for class B copper wire, B-8 for compressed stranded and B-496 for compact stranded conductors. The conductors are individually insulated with ethylene propylene rubber (EPR) per ICEA S-96-659. A soft bare annealed copper grounding conductor is included in the assembly which helps to ensure steady conductivity throughout the life of the cable. The exterior armor of the cable is an aluminum interlocked tape armor that is also available in galvanized steel. The armor serves as the first line of defense against materials or objects that may pose a threat to the conductors. The armor is coated with a yellow sunlight-resistant PVC jacket.

The Interlocked Armor Power Cable – 350MCM - 3 Conductor - 5KV/8KV is a wide-diameter cable designed to transmit medium voltages at a maximum conductor temperature of 105°C. In emergency overload conditions, conductor can tolerate temperatures up to 140°C and in short circuit conditions, the conductor can tolerate temperatures up to 250°C. The cable is approved for use in wet or dry locations and can be installed indoors or outdoors. The cable can be installed aerially, in ducts, cable trays, conduits, or direct burial for circuits not exceeding 5,000 volts. The cable is approved for use in hazardous locations in accordance with National Electric Code.

Specifications:

- Interlocked Armor - Power Cable

- 5kV/8kV UL Type MV-105 or MC, CT USE, 105°C

- Shielded, EPR Insulation

- 8kV, 100% and 5kV, 133% Insulation Level

- Aluminum Armor, Copper Conductors

Application:

For use in harsh environments where maximum conductor protection is required. Used for primary power and feeder circuits in a broad range of commercial and industrial power distribution systems. Approved for use in wet or dry locations at 105°C, for installation indoors or outdoors, aerially, in conduits, ducts, cable trays or direct burial in circuits not exceeding 5000 volts. May be used in NEC Class I and II, Division 2 and Class III, Division 1 and 2 hazardous locations. UL approved for use at 105°C for continuous operation, 140°C for emergency overload conditions, and 250°C for short circuit conditions. Aluminum interlocked armor cable is recommended as an economical alternative to wire in conduit systems.

Conductors:

Soft bare annealed copper per ASTM B-3, Class B stranding per ASTM B-8, with a semi-conducting conductor shield

Insulation:

Ethylene propylene rubber (EPR) per ICEA S-96-659

Grounding Conductor:

Soft bare annealed copper per ASTM B-3, Class B stranding per ASTM B-8 sized in accordance with UL Standard 1072

Armor:

Aluminum interlocked tape armor per UL Standard 1072 and applicable ICEA standards, also available in galvanized steel armor

Jacket:

Yellow sunlight-resistant PVC per UL Standard 1072 and applicable ICEA standards

Flame Tests:

- IEEE 383 (70,000 BTU/hr) Flame Test

- UL 1581 (70,000 BTU/hr) Flame Test

- IEEE 1202 (70,000 BTU/hr) CSA FT4 Flame Test

- ICEA T-29-520 (210,000 BTU/hr) Flame Test

- ICEA T-30-520 (70,000 BTU/hr) Flame Test

Color Code:

ICEA Method 3

Additional Standards:

ICEA S-93-639 (NEMA WC71)

Connectors:

- Explosion Proof, Class 1 Division 2: 424CU series – aluminum exterior components, nickel-plated brass interior components

- Rain Tight: 416MC series – all nickel-plated brass

- For size 750 kcmil, see 424MA series in Section J

| Technical Specifications: | |

| Size (AWG or kcmil): | 350 MCM |

| No. of Conductors | 3 |

| Net Weight: | 5490 |

| Overall Diameter (Inches): | 2.607 |

| Insulation Thickness (Mils): | 115 |

| Jacket Thickness (Mils): | 75 |

| No. of Strands: | 19 |

| Class 1 Div.2 Connector No.: | 424CU09 |

| Rain Tight Connector No.: | 416MC09 |